Precise gear units, efficient motors

Made in Poland

At its Wiechlice and Nowa Sól factories, NORD DRIVESYSTEMS manufactures innovative drive technology such as the high efficiency IE5+ motor and the DuoDrive gear unit/motor combination. This is made possible by advanced production technology and highly trained employees.

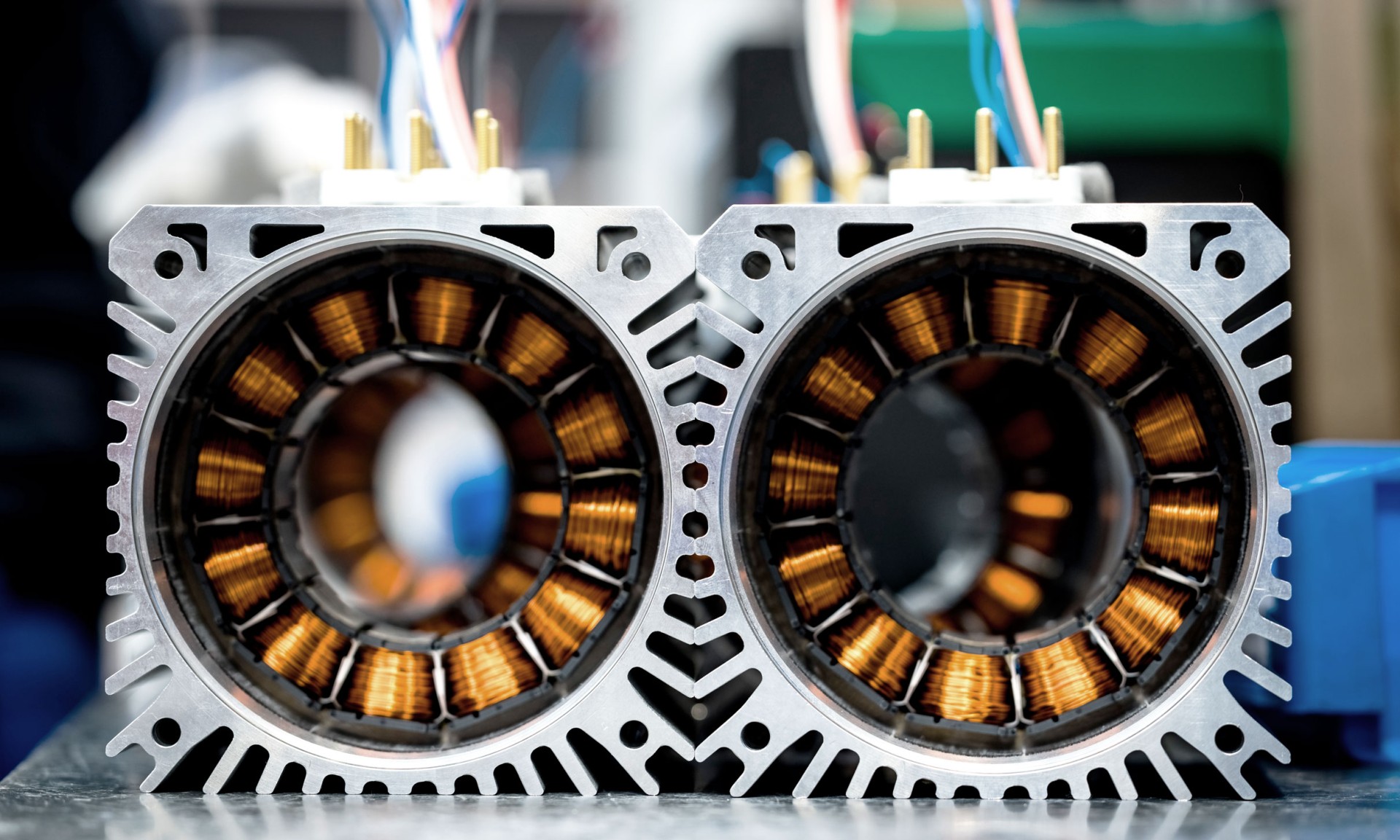

A dozen loosely wound copper wire bundles lie on an aluminium plate. From one side, they are each hooked into the teeth of a cylindrical device. A pneumatic guide reaches into the cylinder from above and pulls the copper wire bundles into the sheet metal packages within a matter of seconds – thus producing a crucial intermediate product in the manufacture of stators for electric motors.

“We have fully automated the winding of the copper wires”, Premysław Sulikowski, the plant manager at the Polish NORD factory in Wiechlice, explains. “We are way ahead with this, as this is well advanced over the worldwide standard in the industry.” Within NORD DRIVESYSTEMS’ international production network, the location in Western Poland is of special importance, as the company’s high efficiency IE5+ motors are manufactured here.

Together with Nowa Sól, which is just 30 kilometres away, Wiechlice forms a dual location that is distinguished by its intelligent, highly automated production technology and competent, highly trained employees. 220 women and men are working in Wiechlice, and about twice as many in the neighbouring factory.

Automated high-tech production

Two automated winding lines, each with an industrial robot feeding ten machines, form the centre of stator production in Wiechlice. After automated winding, experienced specialists manually insulate and bandage the stators and then inpregnate and finally assemble them into the housings. The production consumes up to 2.5 tons of copper per month, and 160,000 stators were manufactured here in 2022.

More than twice as many motors in sizes from 63 to 160 were assembled that year: 365,000. “We receive additional stators from our colleagues at the Italian factory”, Sulikowski says. “The rotors are either from Nowa Sól or Italy.” NORD has a large factory in San Giovanni Persiceto near Bologna. The polish locations are connected with Italy and the main factory in Bargteheide near Hamburg by means of regular truck transportation.

Triple testing of all products

In addition to the stator production and other pre-assemblies as well as the motor production, the testing department is crucial for the high quality standard in Wiechlice. “All products are tested three times at our factory: twice for the stator itself and once for each assembled motor”, Premysław Sulikowski emphasises. A further test is then carried out later at a different factory when the motor is combined with the gear unit into one unit.

Established in 2019, Wiechlice meets the latest requirements for production locations. Work is carried out here on 14 production lines in a two-shift operation. Due to the increasing demand, and also for IE5+ synchronous motors, the factory is currently being significantly expanded. A large expansion will triple the warehouse space and production capacities from mid-2024. In the course of the new construction, deep drilling is also being carried out for the installation of a geothermal system, which will be able to heat the production halls in a CO2-neutral manner in the future. As part of NORD DRIVESYSTEMS’ sustainability strategy, this construction measure is of great importance.

The overall accuracy of the gear unit depends on how precisely our gears are machined. Consequently, quality is our top priority.

Delicately balanced intralogistics system

IE5+ motors from Wiechlice are then delivered to Nowa Sól, 30 kilometres to the North, where they are integrated into helical gear units and thus combined into the extremely efficient DuoDrive gear unit/motor combination. In addition to the headquarters in Bargteheide in Northern Germany, Nowa Sól is home to NORD DRIVESYSTEMS’ second major worldwide gear unit assembly facility. Production manager Adam Strózyk supervises 29 assembly lines, where about 10,000 gear units are produced per week.

To achieve this, more than 100 technicians are working in two shifts. In the in-house paint shop, the gear units are even coated in three layers of protective paint. The two existing painting lines have just been supplemented by a third one. “We paint the gear units either in the standard colours blue or silver or in any colour that our customers request”, Adam Strózyk highlights.

In order to make these production capacities possible, sufficient supplies of the required parts for the assembly workplaces is necessary. NORD has developed a delicately balanced intralogistics system for this: the material flow is organised via an 18-metre high-bay warehouse with 6000 storage spaces and three large Kardex small-parts cabinets. The produced and tested gearboxes are delivered to other NORD locations or directly to the customer via a semi-automatic outbound system.

Decisive benchmark: quality

The quality of the produced gear units is also the decisive benchmark in Nowa Sól. Experienced employees manufacture them at state-of-the-art manual assembly stations, and all gear units are carefully tested. To guarantee the outstanding quality standard, NORD also produces the components that are crucial for the gear units’ precision in-house: input and output gearwheels as well as motor and pinion shafts.

Like oversized ice hockey pucks, the blanks made of different steel alloys lie in dozens of wooden or pallet cages. The machining department of production manager Paweł Stasyszyn uses these to produce high-precision gearwheels. They are shaped by lathes and milling machines to produce the required gear form. After hardening by an external service provider, the gearwheels are given their exact geometry during final precision grinding. Motor and pinion shafts are manufactured on CNC machining centres – in a single step, which further increases the accuracy of the gear unit components.

Precise gearwheels, precise gear units

A total of 70 state-of-the-art turning, milling and CNC machining centres are in operation around the clock in three shifts from Monday to Friday. Paweł Stasyszyn’s team produces over three million parts per year.

"The overall accuracy of the gear depends on how precisely our gears are machined," emphasises Stasyszyn. “Consequently, quality is our top priority.” The design of the hall layout represents this understanding. The inspection department, in which the parts are tested, is at the heart of the mechanical processing hall. “We test every first manufactured part of a series and always one of each shift”, says the production manager, who is also located in the centre of production area with three process engineers who work with him, says. “Added to this are those parts that have been subject to individual inspection during production." For this purpose, around 2000 hand-held measuring devices are available at the processing machines to carry out an initial manual test on the parts.

This way, machine operators, technicians, test engineers and quality controllers all work together to achieve outstanding product quality that benefits the customers of gear units and motors from NORD DRIVESYSTEMS worldwide.