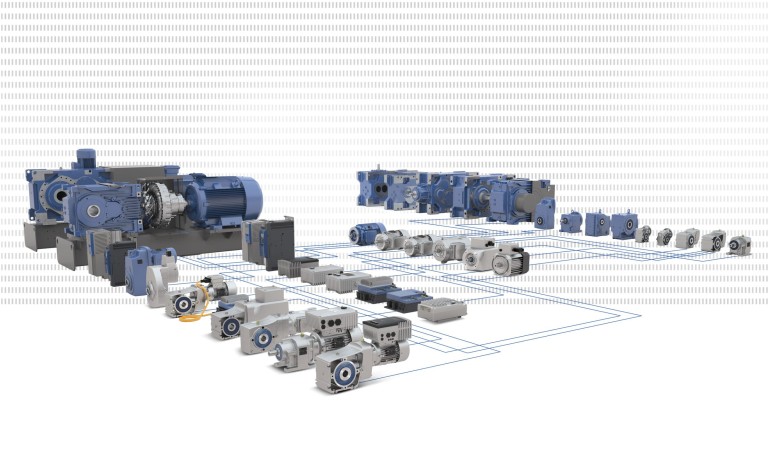

During the last stage of the packaging process – the end-of-line packaging – heavy loads are moved over long travel distances. This requires individual and powerful drive systems.

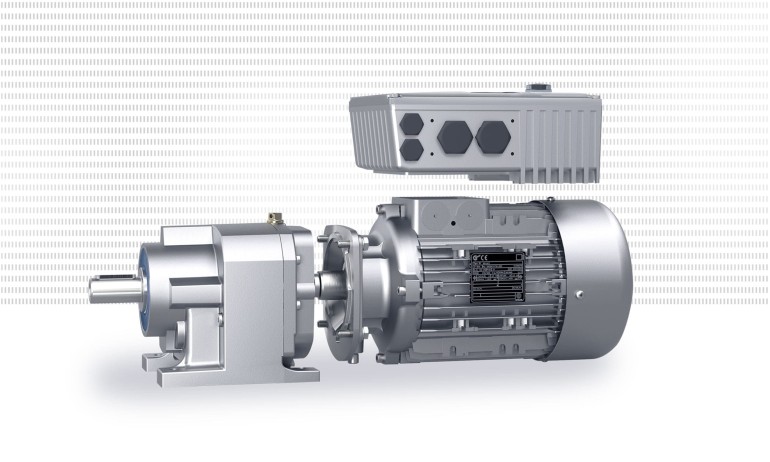

Read our white paper, to find out more about the use of decentrally controlled system solutions with asynchronous motors in end-of-line packaging.

Download white paper now